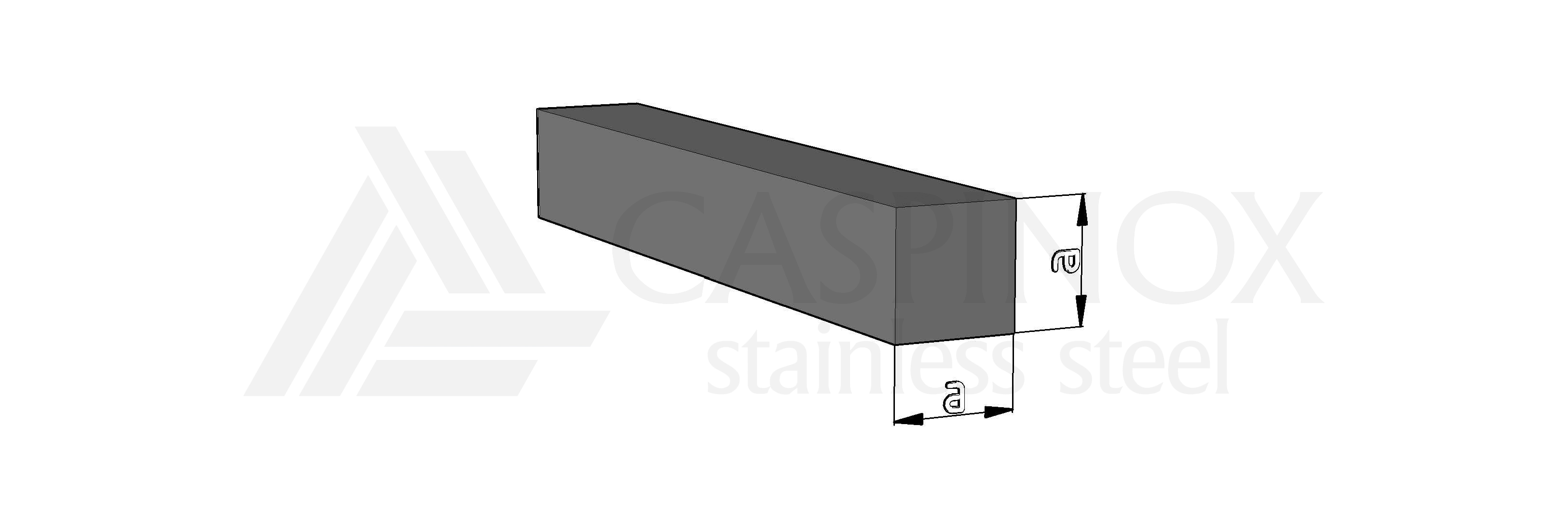

STAINLESS STEEL SQUARE BAR

Calibrated stainless steel is a bar that has square cross section. It is made both by hot rolling (20x20 and more) and cold rolling (correspondingly 6x6 – 60x60) method.

Usually, stainless square is used as rough material in the manufacturing end product in widespread sector ranging from food and chemical industry to construction and machinery.

The most popular filed of use of stainless squares id the manufacturing details for trucks and cars. The products allow to manufacture very durable components, the shelf life of which is measured in decades. The fact that squares made of stainless steel are not almost influenced by the corrosion is undeniable advantage, because it increases the working capacity of mechanisms and machines. It should be noted that, at present, stainless squares are actively involved in the manufacturing rough products for the processing in rolled section and structural steel.

The side of stainless steel square usually varies from six to two hundred millimetres. Stainless steel made of calibrated steel (it has its own manufacturing characteristics and field of use) has the side dimensions from three to one hundred millimetres. However, the dimensions are always able to be changed by the request of the customer.

Types of stainless squares

Stainless squares are divided into several types depending on their surface appearance: matte, polished, mirror and super mirror. Super mirror and mirror squares often have small thickness and weight and used with decorative purposes.